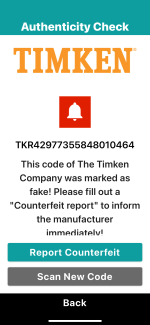

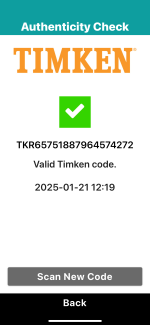

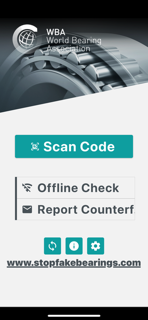

I have two TimeOut trailers. One Camper Deluxe and the other is the Dart. They both use Timken Bearing/Race Set 4 (L44649/L44610). I purchased some from Amazon and NAPA and according to the WBA App (World Bearing Association) all of those were counterfeit. I went to Timken's web site and found a local Distributor, so ordered four from them. Three out of four were counterfeit. Contacted @Timken and no help there. Can someone recommend another brand bearing you have had luck with preferably American made.

-

There were many reasons for the change of the site software, the biggest was security. The age of the old software also meant no server updates for certain programs. There are many benefits to the new software, one of the biggest is the mobile functionality. Ill fix up some stuff in the coming days, we'll also try to get some of the old addons back or the data imported back into the site like the garage. To create a thread or to reply with a post is basically the same as it was in the prior software. The default style of the site is light colored, but i temporarily added a darker colored style, to change you can find a link at the bottom of the site.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Any Recommendations for USA Made Trailer Bearings Other Than Timken?

- Thread starter Dakotaz

- Start date

Not saying that Timken Corp sold them, but one of their Distributors, as well as Amazon and NAPA. There is an APP on Apple that is called WBA that you scan the QR code on the box and it states if it is reported by Timken as counterfeit or legit. I'll try to post a picture of the scan.Surprised that Timken would sell counterfeit bearings how can you tell counterfeit bearings from real?

-

-  -

-

Timken on their website actually suggests using the WBA App to confirm authenticity. When I contacted them, they suggested buying from one of their distributors, which still got me three out of four bearing kits coming up as counterfeit bearing kits.

Last edited:

Probably will have to do that, but just tired of dealing with Timken. Also they will have to order in and then I wait and hope that what they get is real. I doubt Timken sold the counterfeit bearings to the distributor so where else is the distributor buying from? That's why I am asking if anyone knows of another US Supplier. I do appreciate suggestions.Seems to me if you can determine counterfeit, the distributer should be able to do the same. I'd just return the counterfeit to the distributer and instruct them to send you the valid bearings that you expected and paid for.......?

TheMariner

Well-known member

SKF & NSK are a well-known international brands & have distributors in Arizona.

Phil thank you very much for your information. I will look into those brands.SKF & NSK are a well-known international brands & have distributors in Arizona.

Mikey

Well-known member

Myself, and don't take this the wrong way, but I really think you're taking this way too far and over thinking it! SKF and NSK are as good as Timken for this job. What give you the idea you need to change the bearings in the first place, instead of just cleaning and repacking them? Are they loose or feel gravelly in your hand when you cleaned them? The biggest troubles people get into on a trailer wheel bearing is NOT servicing them when they should have. The guys you see beside the road with their wheels off or gone are those who just run them and don't do their homework before they leave. If I were you, I would go to Napa, give them the number off your bearing, tell them you want the bearing and race, and they will probably have SKF, NSK - they are fine companies, been around in the field for a long time, go home, pack them, install them, and not lose a night's sleep.I have two TimeOut trailers. One Camper Deluxe and the other is the Dart. They both use Timken Bearing/Race Set 4 (L44649/L44610). I purchased some from Amazon and NAPA and according to the WBA App (World Bearing Association) all of those were counterfeit. I went to Timken's web site and found a local Distributor, so ordered four from them. Three out of four were counterfeit. Contacted @Timken and no help there. Can someone recommend another brand bearing you have had luck with preferably American made.

Mikey, no problem, I appreciate all comments. Former mechanic here so just like to be certain that my gear is in top shape. I just acquired both of these trailers so I had no history with them. Both had Chinese bearings in them so I purchased the Timken's. I am a firm believer in Timken, except when they are counterfeit, which some of these bearings I have purchased have been.Myself, and don't take this the wrong way, but I really think you're taking this way too far and over thinking this! SKF and NSK are as good as Timken for this job. What gave you the idea you needed to change the bearings in the first place, instead of just cleaning and repacking them? Are they loose or feel gravelly in your hand when you cleaned them? The biggest troubles people get into on a trailer wheel bearing is NOT servicing them when they should have. The guys you see beside the road with their wheels off or gone are those who just run them and don't do their homework before they leave. If I were you, I would go to Napa, give them the number off your bearing, tell them you want the bearing and race, and they will probably have SKF, NSK - they are fine companies, been around in the field for a long time, go home, pack them, install them, and not lose a night's sleep.

Phil up above gave me a good lead on SKF and NSK which I am looking into right now. Will be going with one of these two product lines.

CloverHill

Member

Counterfeit merchandise is through all of the supply chains at this point, even the drugs that you pick up at your pharmacy have a good chance of being counterfeited. Especially with all of the weight loss drugs right now as they are in high demand.Surprised that Timken would sell counterfeit bearings how can you tell counterfeit bearings from real?

Dasmoetorhead

Well-known member

Go to a local trailer dealer or hitch shop. They usually sell all maintenance items needed for trailers.

Mikey

Well-known member

Don't take me wrong, Timken's got a good product, but sometimes you pay a little more for the name than maybe you should!Mikey, no problem, I appreciate all comments. Former mechanic here so just like to be certain that my gear is in top shape. I just acquired both of these trailers so I had no history with them. Both had Chinese bearings in them so I purchased the Timken's. I am a firm believer in Timken, except when they are counterfeit, which some of these bearings I have purchased have been.

Phil up above gave me a good lead on SKF and NSK which I am looking into right now. Will be going with one of these two product lines.

Jackhartjr

Active member

Is it me, or don't you think that Timken should be asking the distributor where they are getting the counterfeit bearings from and going after the source of them?

I totally agree. They did not really seem to care. Like I said earlier, Amazon four bad, NAPA four bad, and the Distributor three out of four counterfeit. Phil up above got me a lead on SKF and NSK and will be using one of those manufacturers.Is it me, or don't you think that Timken should be asking the distributor where they are getting the counterfeit bearings from and going after the source of them?

Found some SKF bearings locally. Thanks to everyone for your suggestions.

Gwolf

Well-known member

Just to clarify - are you saying the Timken bearings are counterfeit because they were not made in the USA?

If that is the reason, then you should be aware that, while Timken has manufacturing facilities in the USA, they also have manufacturing facilities in Mexico and Romania. If the Timken manufacturing facilities are in 3 different countries, it would make sense that they do not manufacture all types of their product in every country where they have facilities. Like many other manufacturing businesses that produce many different sizes and types of a precision product, they probably manufacture some different sizes or types in each of the 3 countries, but all are officially Timken products and are available worldwide. The Timken bearings made in Mexico and Romania are just as much real Timken bearings as those made in USA. Also, Timken has manufacturing facilities in Eastern Europe which may, or may not, be in the European Union or use that location to define their geographical source. Not all countries located in Eastern Europe are members of the European Union.

If that is not the reason that you are saying some of the Timken bearings are counterfeit, then bearings coming from some country not USA, Mexico, or Romania would mean that Timken could be sourcing some of the different sizes from other manufacturers and selling them under the Timken name. I see nothing wrong with them doing that, so long as the bearings are within the standards of Timken made products. Many precision products which were formerly manufactured in the USA are now sourced from other countries and still sold under the long time USA brand name. With the constant mergers, acquisitions, and changes in import/export laws, it is more and more difficult to find a long time established USA brand name that does not have sources or facilities in other countries where the same products can be supplied for a much lower cost.

I am not an expert on Timken Bearings, but I did work in an International Mining Company machine shop where we tore down all types of mining and manufacturing equipment and rebuilt it. A lot of the equipment we repaired was no longer manufactured at all, or had been replaced in the manufacturing process by different equipment in the more modernized facilities. Ordering replacement bearings was first attempted using the bearing maker name and the stamped numbers on the old bearings. If that failed, the bearings were measured and the required size was used to locate replacement bearings of some other brand name. Some of the parts, such as gears, flywheels, spacers, etc. had up to a 5 year back order time, and had to be cannibalized from scrap yard equipment or custom ordered as one off gears, etc, if we did not have the proper machinery to manufacture a new one in the local shop.

If that is the reason, then you should be aware that, while Timken has manufacturing facilities in the USA, they also have manufacturing facilities in Mexico and Romania. If the Timken manufacturing facilities are in 3 different countries, it would make sense that they do not manufacture all types of their product in every country where they have facilities. Like many other manufacturing businesses that produce many different sizes and types of a precision product, they probably manufacture some different sizes or types in each of the 3 countries, but all are officially Timken products and are available worldwide. The Timken bearings made in Mexico and Romania are just as much real Timken bearings as those made in USA. Also, Timken has manufacturing facilities in Eastern Europe which may, or may not, be in the European Union or use that location to define their geographical source. Not all countries located in Eastern Europe are members of the European Union.

If that is not the reason that you are saying some of the Timken bearings are counterfeit, then bearings coming from some country not USA, Mexico, or Romania would mean that Timken could be sourcing some of the different sizes from other manufacturers and selling them under the Timken name. I see nothing wrong with them doing that, so long as the bearings are within the standards of Timken made products. Many precision products which were formerly manufactured in the USA are now sourced from other countries and still sold under the long time USA brand name. With the constant mergers, acquisitions, and changes in import/export laws, it is more and more difficult to find a long time established USA brand name that does not have sources or facilities in other countries where the same products can be supplied for a much lower cost.

I am not an expert on Timken Bearings, but I did work in an International Mining Company machine shop where we tore down all types of mining and manufacturing equipment and rebuilt it. A lot of the equipment we repaired was no longer manufactured at all, or had been replaced in the manufacturing process by different equipment in the more modernized facilities. Ordering replacement bearings was first attempted using the bearing maker name and the stamped numbers on the old bearings. If that failed, the bearings were measured and the required size was used to locate replacement bearings of some other brand name. Some of the parts, such as gears, flywheels, spacers, etc. had up to a 5 year back order time, and had to be cannibalized from scrap yard equipment or custom ordered as one off gears, etc, if we did not have the proper machinery to manufacture a new one in the local shop.

Gwolf no not at all. I confirmed the Timken bearings were counterfeit by using the (World Bearing Assoc) WBA App on my iPhone. Timken on their website suggests using this app to confirm if bearings purchased were manufactured by a Timken Plant in the USA or another country, or by a counterfeiter. The app scans the QR code on the Timken box. In post 3, I attached a picture of what the app brings up after the QR scan.Just to clarify - are you saying the Timken bearings are counterfeit because they were not made in the USA?

If that is the reason, then you should be aware that, while Timken has manufacturing facilities in the USA, they also have manufacturing facilities in Mexico and Romania. If the Timken manufacturing facilities are in 3 different countries, it would make sense that they do not manufacture all types of their product in every country where they have facilities. Like many other manufacturing businesses that produce many different sizes and types of a precision product, they probably manufacture some different sizes or types in each of the 3 countries, but all are officially Timken products and are available worldwide. The Timken bearings made in Mexico and Romania are just as much real Timken bearings as those made in USA. Also, Timken has manufacturing facilities in Eastern Europe which may, or may not, be in the European Union or use that location to define their geographical source. Not all countries located in Eastern Europe are members of the European Union.

If that is not the reason that you are saying some of the Timken bearings are counterfeit, then bearings coming from some country not USA, Mexico, or Romania would mean that Timken could be sourcing some of the different sizes from other manufacturers and selling them under the Timken name. I see nothing wrong with them doing that, so long as the bearings are within the standards of Timken made products. Many precision products which were formerly manufactured in the USA are now sourced from other countries and still sold under the long time USA brand name. With the constant mergers, acquisitions, and changes in import/export laws, it is more and more difficult to find a long time established USA brand name that does not have sources or facilities in other countries where the same products can be supplied for a much lower cost.

I am not an expert on Timken Bearings, but I did work in an International Mining Company machine shop where we tore down all types of mining and manufacturing equipment and rebuilt it. A lot of the equipment we repaired was no longer manufactured at all, or had been replaced in the manufacturing process by different equipment in the more modernized facilities. Ordering replacement bearings was first attempted using the bearing maker name and the stamped numbers on the old bearings. If that failed, the bearings were measured and the required size was used to locate replacement bearings of some other brand name. Some of the parts, such as gears, flywheels, spacers, etc. had up to a 5 year back order time, and had to be cannibalized from scrap yard equipment or custom ordered as one off gears, etc, if we did not have the proper machinery to manufacture a new one in the local shop.

Last edited: