Flamewinger

New member

I was installing a BRP belt tensioner with Lamonster pully from Spyderpops. I got the instructions from the BRP web site and it indicates 137 lbf*in and I didn't think and went to tighten the top bolt to 137 foot pounds and the head broke. I was able to drill down into it and get an EasyOut to grip but the tightness of the bolt and the thread locker was too much for the EasyOut and the head broke. So now I have chipped as much of the EasyOut but can't get it all and the drill bit won't bite. I tried heating the bolt and using a left handed drill bit but that doesn't work either. SO . . .

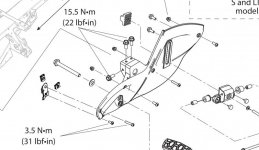

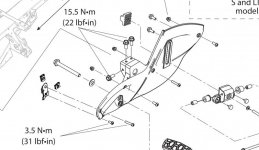

I want to remove the part the floorboards are mounted to and take it to a friend that can get it out. Can I just unbolt it or do I need to support the engine or some part of the bike while it's out? Notice the difference in torque values, both say 15.5 N*m but the instructions have 137 lbf*in and the service manual shows 22.

BRP Instructions ---------------- Broken bolt

MY online Service manual which doesn't show how to replace the belt. (or I can't find it)

I want to remove the part the floorboards are mounted to and take it to a friend that can get it out. Can I just unbolt it or do I need to support the engine or some part of the bike while it's out? Notice the difference in torque values, both say 15.5 N*m but the instructions have 137 lbf*in and the service manual shows 22.

BRP Instructions ---------------- Broken bolt

MY online Service manual which doesn't show how to replace the belt. (or I can't find it)